Want to talk about a project?

Our team of fiberglass experts are here to discuss applications, product designs, and much more.

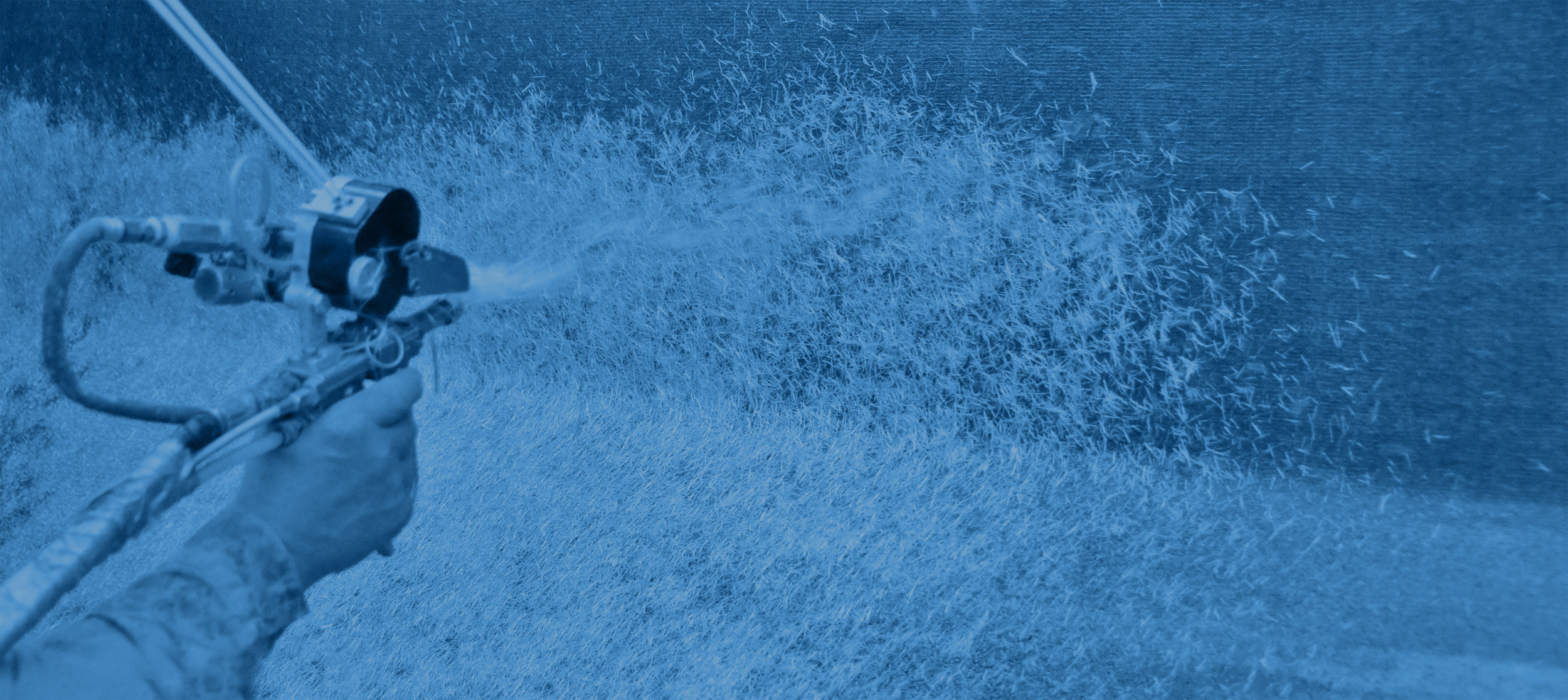

OUR Expertise

What our customers are saying!

Posted onTrustindex verifies that the original source of the review is Google. Damaged the back and keel of boat when taking off the trailer (it fell off onto the cement boat ramp). Brought it in to Carstens for repair. Scotty not only did a fantastic job, he did it in an unbelievable time frame and at a reasonable cost. Good vibes seem to be the norm around here. I've found my fiberglass repair nirvana.Posted onTrustindex verifies that the original source of the review is Google. Carstens Industries, Inc. is a very well organized, tidy and fiscally well managed facility. They are deeply concerned to provide a clean and healthy work place for their employees, and this level of concern is reflected in the quality of their product. I would highly recommend them as a reliable and trustworthy vendor.Posted onTrustindex verifies that the original source of the review is Google. Top notch speedy service for repairs on my old Pintail. Almost a new boat in under a week. Best marsh/rice boats on the market in my opinion. We have 2 Pintails and 1 Mallard in our camp.Posted onTrustindex verifies that the original source of the review is Google. Top of the line duck boats and the new deer blinds are the best in the industry! Great customer service with friendly sales representatives.Posted onTrustindex verifies that the original source of the review is Google. AWESOME deer stand and would buy from again, as we brought one of their first ones in production. They were selling them at the state fair. Great deer stand!!! We love it !!!

Address

PO Box 185

733 W. Main St.

Melrose, MN 56352

PHONE

320-256-3919

WORKING HOURS

Monday-Thursday: 6:00am – 4:30pm

Friday – Closed

Saturday: Closed

Sunday: Closed